Shale is a big part of the U.S. energy industry supplying more than 63% of gross domestic oil and gas production, but it’s getting hit hard. Drilling new wells to offset steep production declines is difficult in the current capital-constrained environment. Current lower oil prices and decreased demand have made capital extremely limited for new drilling and completions. Added to these budget restraints are rising ESG pressures and discussions of potential regulations from a change in presidential administrations. It’s a lot to handle and poses a difficult challenge for producers — how to extract more oil from existing wells while maximizing sustainability and how to do so quickly and cost-effectively.

New, environmentally-friendly hydraulic fracturing technologies are being introduced with the unique ability to outperform surfactants in maximizing initial production, maintaining those rates to extend the total life cycle of the well and improving profitability. A top solution is biosurfactants — deemed one of the most promising emerging technologies that’s both environmentally friendly and profitable. Biosurfactants offer benefits when applied in existing wells for enhanced oil recovery as well as when used in hydraulic fracturing of new wells.

Biosurfactants are 100% naturally produced and have many advantages over traditional, hydrocarbon-based surfactants, including extremely low toxicity, high activity at elevated temperatures and low critical micelle concentrations that require as little as 1/50th the dosage rate. They can be used at a wide range of pH values and also perform well in high-salinity brines with elevated divalent ions, which can be challenging for synthetic surfactants.

Recently starting use in hydraulic fracturing completions by oil innovation company Locus Bio-Energy Solutions, green biosurfactant solutions show an unmatched ability for displacement into the smallest reservoir pores to mobilize more oil than traditional surfactants, improving initial flow back performance and increasing total estimated recovery while also enhancing ESG profiles. The biodegradable biosurfactants outperform traditional surfactants in enhancing production in existing assets and improving production when used in new completions, at lower dosage rates and costs.

The success of biosurfactants comes from their unique multifunctional properties that solve the biggest shale challenges:

Reaching and Mobilizing Otherwise Immobile Oil

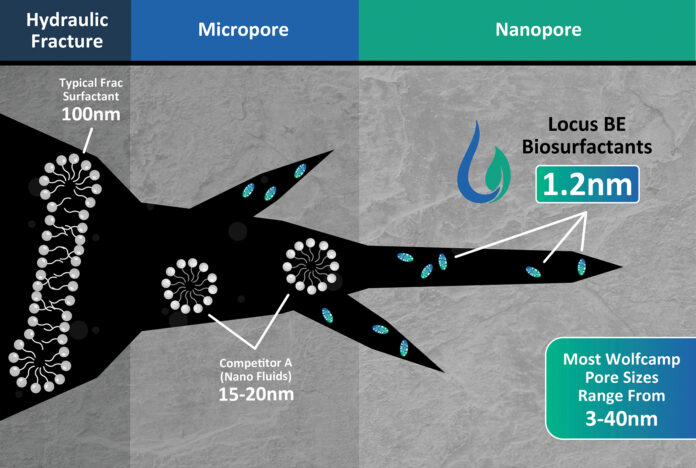

Biosurfactants can penetrate the smallest shale rock “nanopores” that other treatments can’t reach, mobilizing otherwise immobile oil and enhancing recovery in unconventional tight formations where pore throats are extremely small (ex: Wolfcamp shale with nanopores ranging from 3-40 nm). This is due to their small micelle size and lower dosage requirements.

Biosurfactants form micelles that are less than 2 nm in diameter, significantly smaller than the micelles formed by chemical surfactants (~100 nm) and nanoparticles (15-20 nm). This increases penetration in the reservoir during hydraulic fracturing and mobilizes oil from even the tightest shale reservoirs.

Cost-Effectively Increasing Oil Recovery

Biosurfactants effectively mobilize oil by reducing the “drag” between oil and the reservoir rock surface, resulting in maximized oil recovery and minimized fluid costs. They offer faster and lower surface/interfacial tension reductions and an unsurpassed ability to alter surface wettability at lower ppm levels and up to 50X lower concentrations. This is due to the critical micelles concentration (CMC) of biosurfactants, ranging from 1 to 2,000 mg/L. In comparison, interfacial (oil/water) tensions are typically 1 mN/m, and surface tensions are 30 mN/m. Biosurfactants can reduce water surface tension to 25 mN/m and can also reduce the interfacial tension of water/hexadecane to <1 mN/m.

Sustaining Production Enhancements

Unlike synthetic surfactants, which do not adsorb significantly onto reservoir rocks and are typically flushed out in early flow back, up to 50% of biosurfactants are retained by the minerals in shale reservoirs. After providing immediate production boosts during early flow back, these biosurfactants slowly desorb over weeks and months to ensure long-term positive impacts on fluid properties and long-term mobilization of oil after flow back. And because these biosurfactants are effective at extremely low dosage rates, they continue to boost production performance for months after application.

When used as a tertiary enhanced oil recovery process in existing wells, these sustained production enhancements are being acknowledged by state government agencies for qualification in tax credits. For example, the Texas Railroad Commission (Texas RRC) approved Locus Bio-Energy’s biosurfactants as a tertiary enhanced oil recovery technology, qualifying users for a 50% annual severance tax credit for the next ten years on all oil produced — as long as a production increase is maintained.

Increasing Mobility and Extending Well Life Cycle

Biosurfactants break up organic deposits and keep them in suspension, preventing post-completion fouling, ensuring long-term profitable well operations, and extending the well’s total life cycle. Fluids used during hydraulic fracturing can lower oil temperature and cause wax precipitation, making the well unable to reach maximum recovery, slowing cleanup and decreasing production. Biosurfactants outperform xylene and other BTEX solvents in wax dispersion and keep it in suspension, increasing production by removing blockages. The slow desorption of these biosurfactants inhibits paraffin redeposition for many months after application, extending oil recovery benefits.

Exceeding ESG Requirements

Biosurfactants maximize ESG compliance by reducing the need for new drilling, minimizing the use of BTEX solvents as chemical “carriers,” lowering water usage, reducing the carbon footprint of operations and providing treatments with low acute toxicity that are safe for handling and the environment. Current solutions available for use in shale wells from Locus Bio-Energy Solutions are naturally produced from renewable feedstocks, 100% non–GMO and fully biodegradable within 30 days, making them suitable for fragile environments. An analysis done by the oil company found that their water-based biosurfactants had 91% lower toxicity than that of reference surfactants, with a 37% lower carbon footprint.

The cost-effective commercialization of green biosurfactants in the oilfield by companies like Locus Bio-Energy allows producers to maximize sustainability without sacrificing performance and profit. Biosurfactants are replacing synthetic chemistries at lower costs (<1/50th dosage rate), getting more from current assets and extending the lifespan. Their introduction has helped oil operators boost initial production (IP), sustain those higher rates for longer periods and maximize estimated ultimate recovery (EUR) — resulting in much-needed increases in profitability and return on investment (ROI).

About the author: Martin (Marty) Shumway is a licensed Professional Engineer (PE.72266), Certified Petroleum Geologist (CPG #6025) through AAPG and an industry speaker with more than 20 years of experience in the mining and petroleum industries. He currently serves as a Technical Director for the award-winning biosurfactant company, Locus Bio-Energy Solutions. He earned both his Bachelor’s and Master’s degrees in Engineering from Ohio State University.