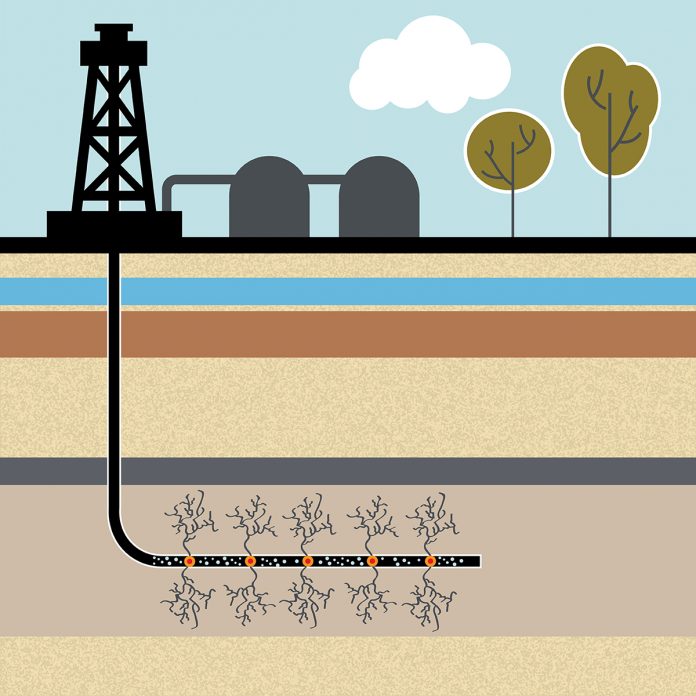

During hydraulic fracturing well stimulation, one of the costliest setbacks that can occur is a screen out, a condition in which pump pressure levels unexpectedly rise rapidly in excess of the safe-operating parameters of the wellbore or wellhead equipment.

This condition, which occurs in up to 25% of well completions, requires immediate cessation of pumping to perform time-consuming drill-outs to clear any obstructions. Considering lost production time and added steps, a single screen out can cost as much as $150,000.

Now, a self-destructing ball and large bore plug system is promising to resolve screen outs without operator intervention. The ball is designed to automatically self-destruct at a predetermined time (usually 3-4 hours) after being exposed to sustained pressure greater than 1500 psi. Like other dissolvable balls on the market, any fragments quickly dissolve within the wellbore in a few days. This clears the blockage, resolves the screen out condition and allows stimulation to resume without further delay.

The technology, developed with the assistance of an aerospace defense contractor responsible for explosive applications such as those used for emergency ejections of pilots on jet planes, can speed natural gas well completion and allow fracking operations to bring the product to market faster.

“Screen out is just about the worst thing that can happen while you are pumping,” says Dave Hornak, an oil and gas industry consultant and previous Manager of Reservoir Stimulation at a firm that completed over 180 wells last year.

According to Hornak, the previous fracking company he worked for had several crews working 24/7 and were installing an average of 30 plugs in each of the 180 wells. Given the volume, screen outs were “something to avoid if at all possible.”

Screen outs often occur when the proppant (sand or other solids) in fracture fluid restricts flow within the wellbore or into the perforations. The restriction causes a rapid rise in pump pressure.

To resolve the screen out, Hornak says his crew would have to rig down the wellhead and pull in a large coil tubing unit into the well under pressure and clear any obstruction, which could take a day or more.

In order to improve his firm’s reservoir stimulation process, Hornak researched and then tested a self-destructing ball for large bore plugs, called DetBall. The product was patented by Ceramic Technologies Corp., a Houston-based company that provides advanced material solutions to a variety of industries including oil and gas.

The self-destructing hollow ball (made of a Mg/Al alloy with a small amount of internal explosive), is designed to detonate at a preset time with a precisely controlled, minimal force sufficient to break the ball apart and not damage the plug or surrounding casing. The remaining fragments are water-soluble and will dissolve in 2-3 days.

For safety and effectiveness in preventing screen out, the ball is designed to self-destruct after being exposed to a sustained pressure greater than 1500 psi. A timer counts down until the ball self-destructs at a pre-set interval 3-4 hours later. As an added safety mechanism, if the ball is ever brought to the surface after activation, the lack of pressure at the surface will ensure it does not detonate.

To create the self-destructing ball, Ceramic Technologies Corp. partnered with Simsbury, Connecticut-based Ensign-Bickford Aerospace & Defense Company, a global leader of precision energetics systems and innovative explosive and non-explosive solutions. The company is responsible for developing solutions in aerospace, such as explosive charges used for automatic ejection of pilots in jet planes.

“What is unique about the DetBall is the fact that you can time the detonation of the ball,” says Hornak. “All you have to do is wait a few hours for the ball to detonate. With the ball gone, the plug is open and you don’t need to bring in a coil tubing unit to correct your problem. In theory, everything below you in the wellbore is now open. So, you can pump into open perfs, flush the wellbore or put down another ball and plug and go about your business.”

Hornak says he and his crew tested the self-detonating DetBalls in three fracking wells and no screen out condition occurred. He also tested the balls under simulated high-pressure conditions to ensure they performed as expected.

When we tested the balls, we put them in place, increased the pressure and then waited for them to pop,” says Hornak. “When that happened, we saw the pressure drop immediately, which indicated the balls [self-destructed] as designed.”

According to Hornak, this approach would have significantly improved his work crew’s completion efficiency if a screen out had actually occurred.

“Since our pump time was two hours, if we had a failure after 90 minutes, all we would have had to do was wait for the ball to pop,” he concludes. “Then we would be able to pump down the wellbore and go on with our process. That is so much better than having to do a drill out.”

For more information: Call 281-556-8495; email: [email protected]; visit www.certechinc.com; or write to Ceramic Technologies Corp. at 1015 Redcedar Lane, Houston, TX 77094.

Shale Oil & Gas Business Magazine